A timber arbour

Large enough to span a path and act as an entranceway, it’s made from treated pine for durability with no special tools required.

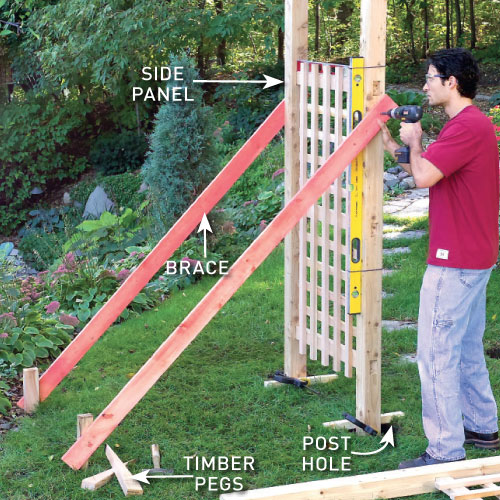

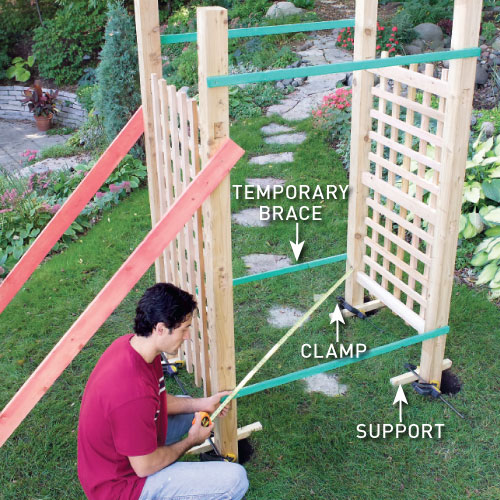

Most of the cutting and joinery can be done in the workshop, then it will take about half a day to assemble the arbour in its final location.

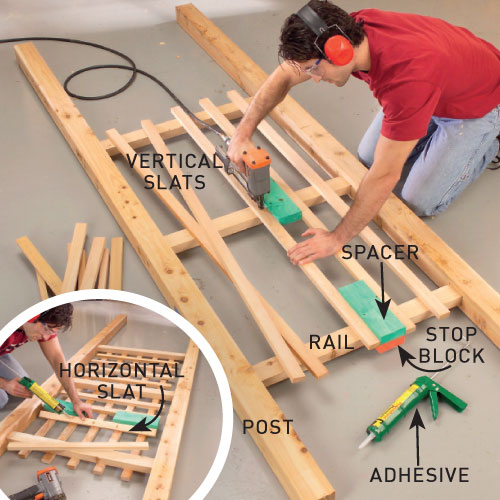

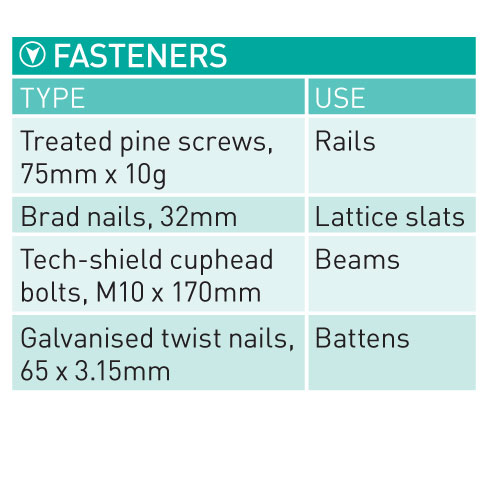

Save time by using a brad nailer when building the latticed sides, and a tablesaw for cutting the timber. If you don’t have these tools, a hammer and circular saw will still do the job.

Allow a full weekend to build the arbour, applying an oil-based stain to protect the timber, then plant climbers to train over the lattice.

A simple structure

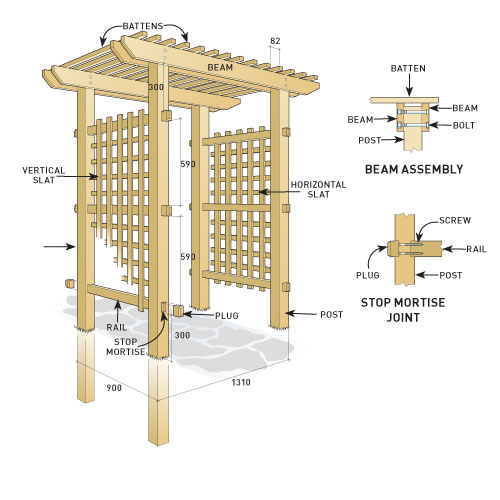

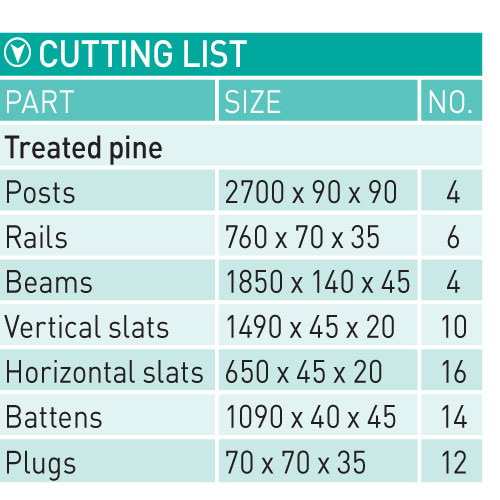

The arbour is made of four posts concreted in the ground and joined by rails, then slats attached to make the latticed sides. The top consists of beams and battens.

The rails are secured in shallow housings called stop mortises in the posts, with matching timber plugs on the other side to create the illusion the rails go the whole way through.

A drill press is the best tool for drilling perfectly vertical holes in timber and will speed up cutting the stop mortises, or you can use a drill guide with a depth collar.

A Forstner bit is designed to cut wide, shallow holes with a flat base, so it is the best type to use when cutting the stop mortises. Drill pairs of holes to remove most of the waste, then square up the corners with a chisel.

Unlike a spade bit, it has a short central spur and sharp, level blades mounted on a flat disc to make it easier to control and more precise.

Exterior timber

The garden arbour is built from 90 x 90mm treated pine posts rated H4 for in-ground use, with the rails, beams and slats cut from H3 rated treated pine.

Use a tablesaw to cut the slats to size from 70 x 45mm timber stock, getting three 20mm thick sections from each length. Cut the battens from 90 x 45mm timber, getting two 40mm thick sections from each length.

If the arbour is to be painted, you can use pre-primed, H3 LOSP finger-jointed treated pine in 42 x 18mm and 42 x 42mm sizes.

Cutting the beams

For the decorative tapers at the beam ends, use a circular saw or mitresaw to cut 100 x 100mm triangles off the base corners.

Round over the edges slightly using a block plane or trim router with a 6mm roundover bit.

Mark the positions for the bolt hole centres 295mm from the ends, and 30 and 100mm up from the base edge of the beams.

Bore the 13mm deep recesses for the bolt heads and nuts on one face of each beam using a drill and 25mm spade bit. To drill the bolt holes the rest of the way through, use a 10mm twist bit.

Step 1. Cut stop mortises

Position the posts side by side then clamp, using a builder’s square to mark the locations of the stop mortises for the rails and plugs. Use a 35mm Forstner bit to drill overlapping holes 20mm deep at each marked location, cutting away the waste with a 25mm chisel.

Step 2. Secure the rails

Insert the rails into the stop mortises between two posts, stand the assembly on edge and tap the pieces together until the inside measurement between the posts is 720mm. Secure with pairs of screws through the stop mortises. Apply a coat of sealer or paint to the stop mortises.