Brilliant bar clamp cover

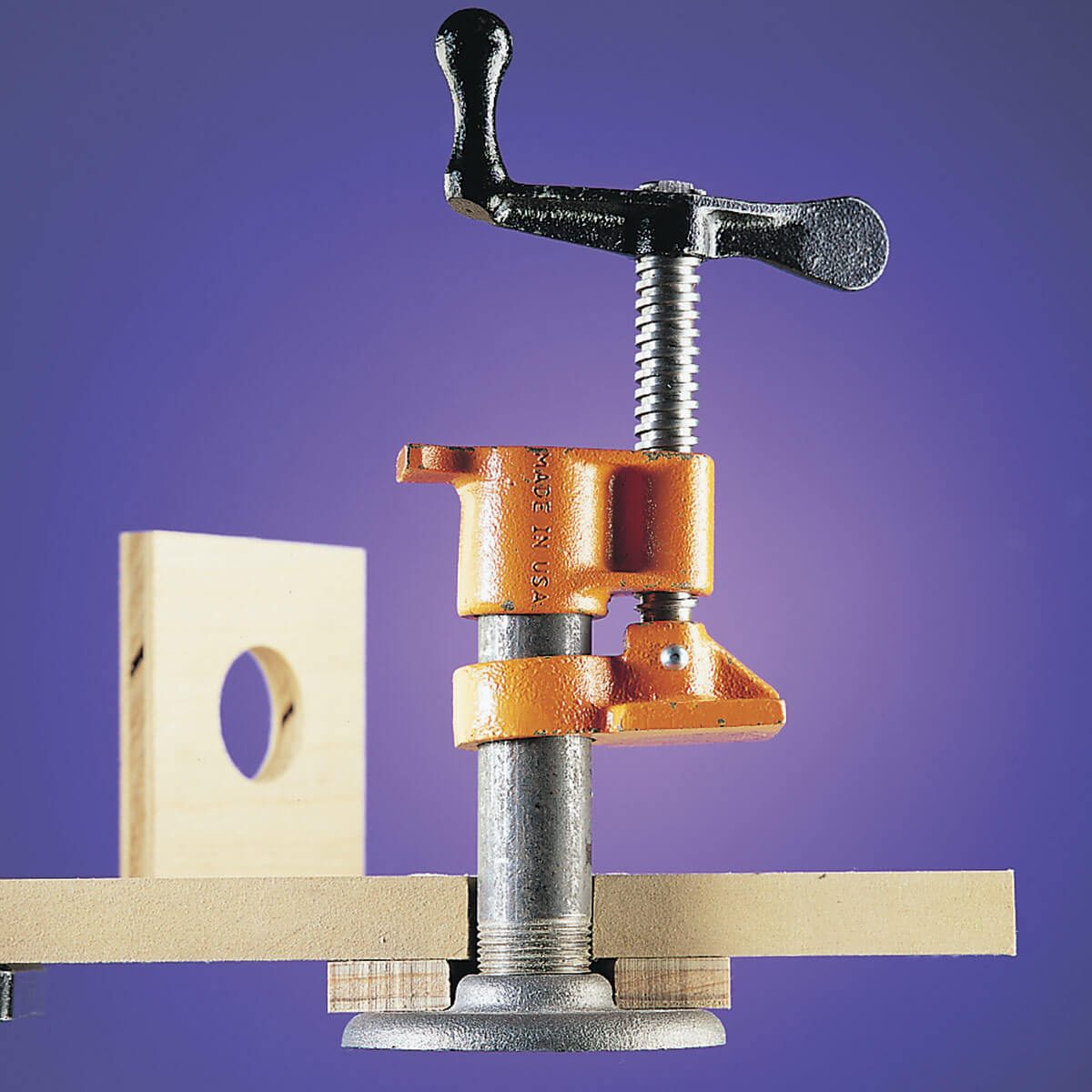

Iron pipe clamps can easily mar softer woods or react with the glue to stain the wood. My solution is to cut a section of plastic PVC pipe to size and place it around the pipe. If you have several short lengths, you can space them strategically to accommodate different widths of stock wood.

Overhead spring clamp storage

If you have a shop in the garage, try this tip. Clip all of your spring clamps on the top garage door brace. The clamps are always right at hand whether you’re working with the door shut or al fresco.

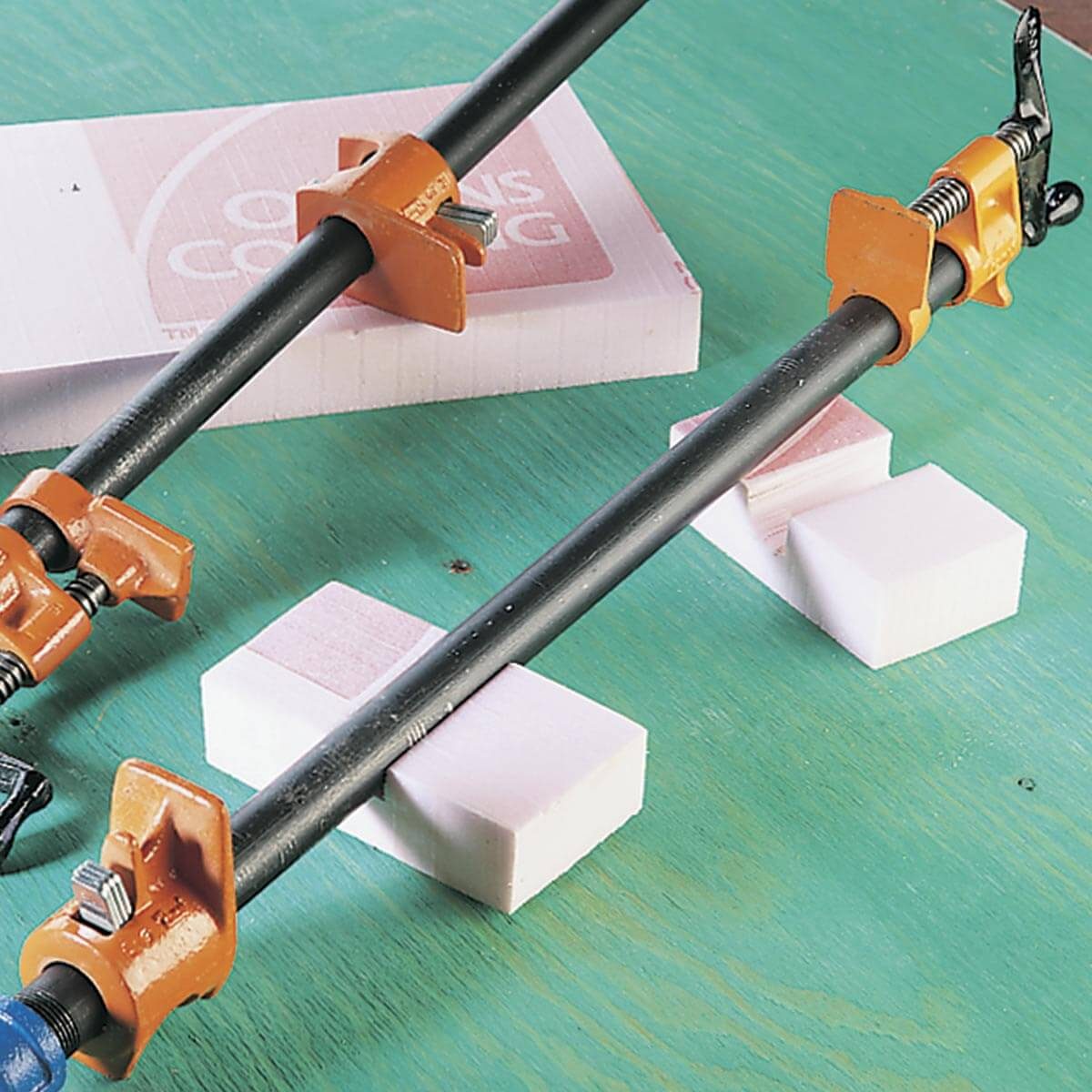

Foam stabilisers

Do your pipe and bar clamps flop over during adhesive jobs – and cause you to come unglued along with the boards? Make supports for your clamps from 38mm thick rigid foam insulation. Use a utility knife or saw to cut friction-fit slots for the pipes or bars. Now the clamps – and you – will remain stable during adhesive jobs.